Frequently asked questions.

Frequently asked questions.

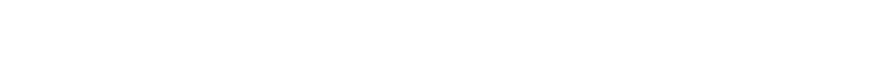

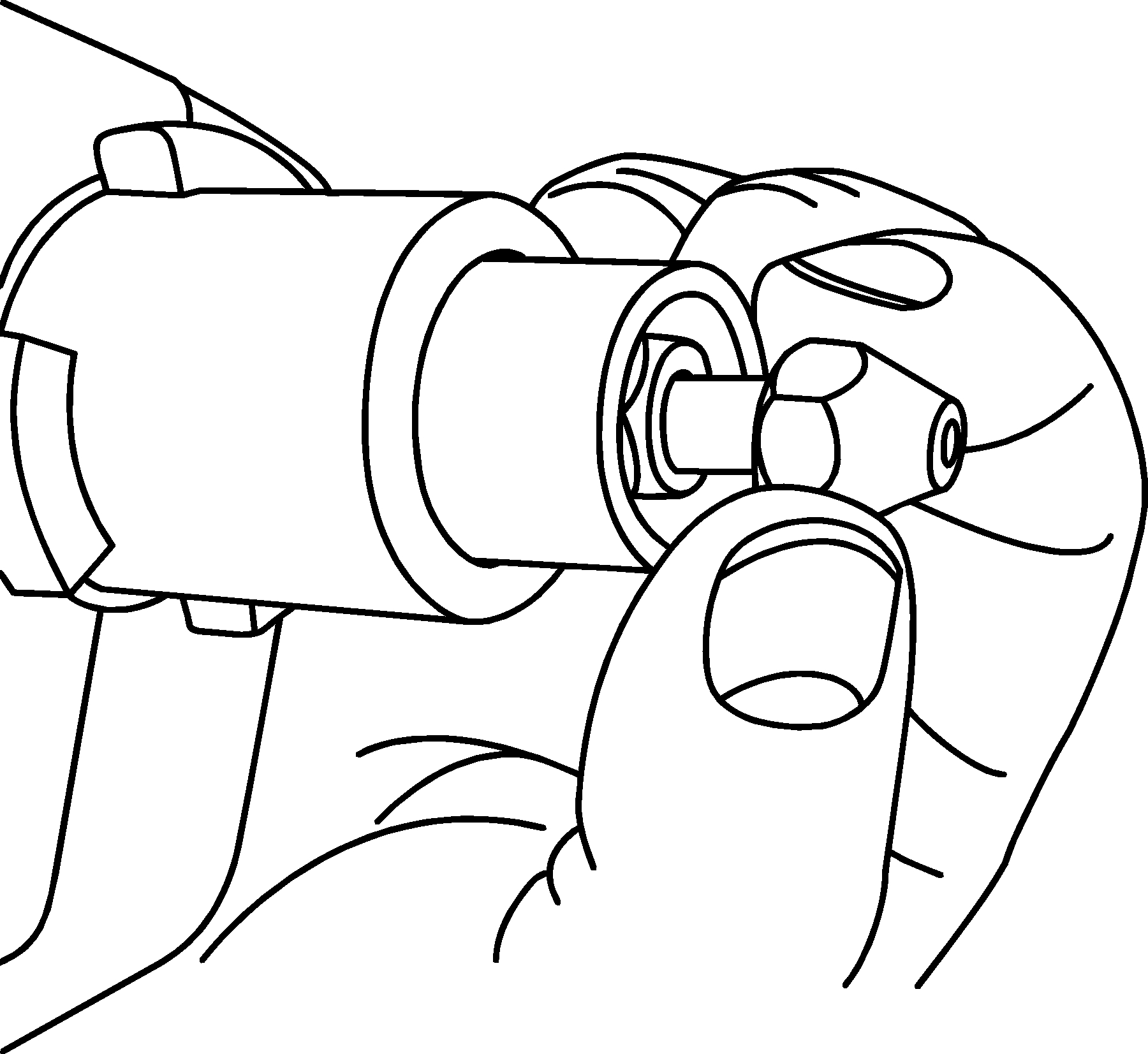

See the figures below. First, install the stud electrode tip, tapered end first, and rotate slightly for a tight fit. Next, insert a welding pin into the electrode, pushing firmly to seat the electrode in the Manga Pin System (MPS) holder. The MPS holder will prevent the pin from falling out in any welding position. See instruction manual for more information.

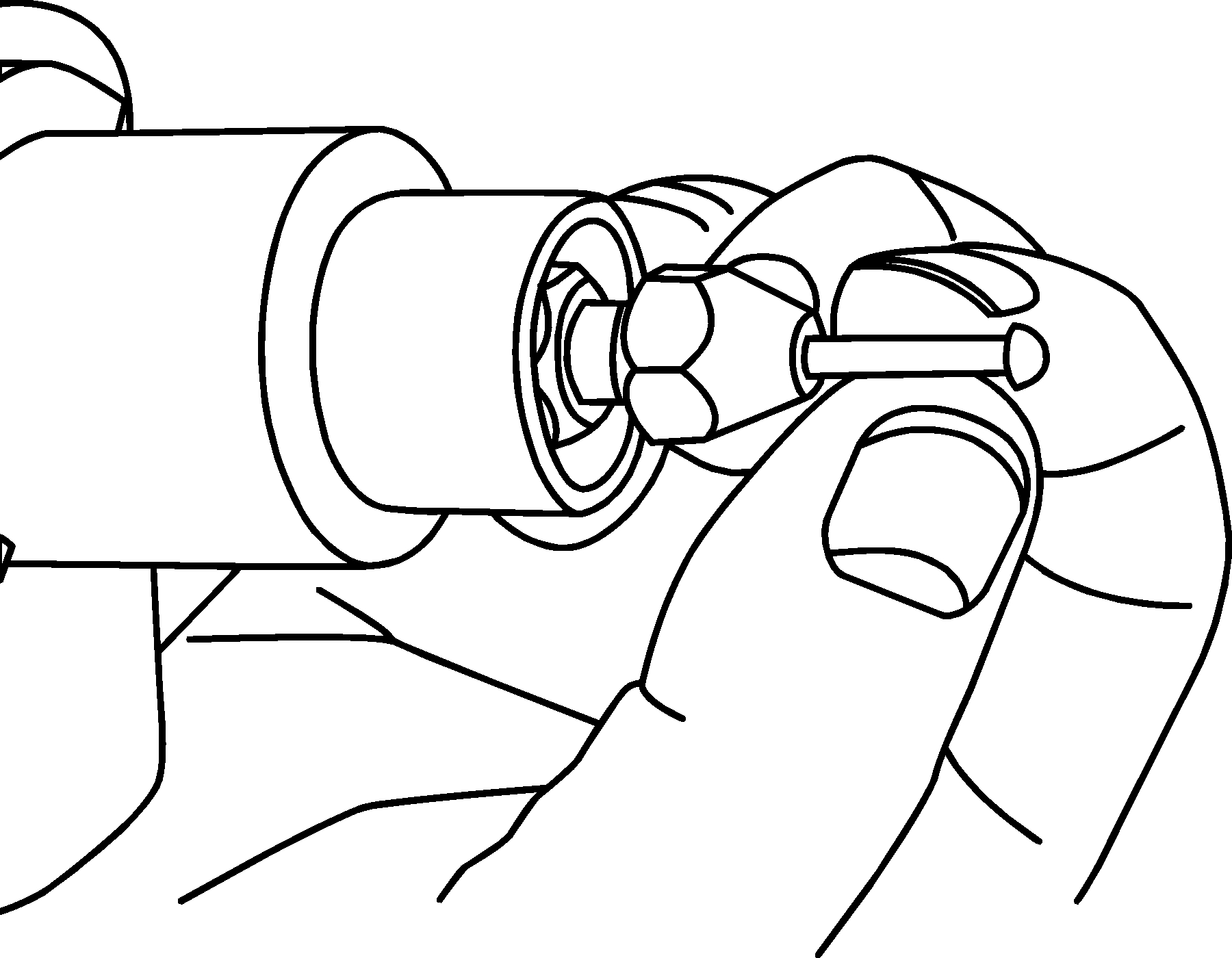

Before using tool on a critical area, pick an area to test operation. Start tool and bring wheel in contact with work surface. With wheel rotation shown, start at right side of adhesive and work to the left, applying light pressure. A slight up and down motion will speed removal. For maximum wheel life, a speed of 1500 RPM is recommended. Optimal speed will vary with thickness of adhesive residue, with heavier residue requiring a lower speed. As a rule of thumb, the higher the speed, the lighter the pressure required. With proper operation, wheel will not harm clear coat and no cleanup is required. Replace wheel when outer diameter approaches 2″, thus preventing accidental contact with metal washer.

Mount filter as close to possible to point of use. Allow at least 20 feet of piping between air compressor outlet and filter as this will allow discharge air to cool sufficiently for proper filter operation.

Install appropriate fittings needed to adapt filter to in-place piping. A ball-type or other positive shutoff valve or disconnect should be installed upstream of the filter to isolate filter for maintenance. Apply pipe thread compound to male threads only. Do not over tighten fittings.

Note direction of airflow before installing filter; “IN” – connection to compressed air supply, ”OUT” – connection to tool or equipment.

Filter should be replaced before the element has become saturated and will no longer trap water. The following general guidelines may be used for the replacement interval:

- Heavy use on dirty air systems – Daily

- Moderate use on average air systems – Weekly

- Intermittent use on clean air systems – Monthly

As these air filters are high-efficiency, absorbent type, depth filters; periodic changes of the cellulose elements are required. The effective life of the element will depend on the moisture content of the compressed air and the flowrate.

As conditions vary widely between applications, only general guidelines can be provided for filter change intervals. Actual change interval should be determined in the field.

Dry Air Conditions – When used in relatively dry conditions, such as downstream of a desiccant dryer or refrigerated air dryer, the change interval should be several weeks. When first installed, the element should be examined after two weeks to determine proper interval.

Moist Air Conditions – When used on a compressed air system with no drying equipment, change interval will be greatly reduced. When first installed, the element should be examined daily until the proper interval is determined. A dry element will absorb approximately 6 to 8 fluid ounces of liquid and should be changed before it becomes completely saturated.

Extremely Moist Air Conditions – Under these conditions, a water separator, with a drain, should be installed in the air line directly upstream of the filter. The separator will remove a large majority of the condensed moisture in the airstream, effectively extending the life of the cellulose element in the Motor Guard filter.

To prevent damage to your air system and components, only genuine Motor Guard replacement elements should be used.

Motor Guard disposable spray gun filters are bi-directional and can be installed with either end connected to the air supply. Use appropriate fittings to install on the spray gun or air tool. The direction chosen should be maintained for the life of the filter installed.

If you are installing multiple types of Motor Guard air preparation products or mixing different brands, the preferred order of installation is:

- Particulate Filter

- Oil Coalescing Filter

- Oil Adsorbing Filter

- Desiccant Dryer

- Pressure Regulator

The part number for the replacement element is Model M-723 and is available in a 4-pack. To prevent damage to your air system and components, only genuine Motor Guard replacement elements should be used.

All Motor Guard products are covered by a limited one-year warranty against defects in workmanship and material. In addition the following extended warranties currently apply:

In addition to the above one year limited warranty, Motor Guard Magna-Spot Stud Welders are covered by an additional Four (4) Year Extended Warranty.

In addition to the above one year limited warranty, Motor Guard Magna-Flex Spray Booth Hoses are covered by an additional One (1) Year Extended Warranty.

For details of the Motor Guard limited warranty, click here.

Motor Guard products are sold through a network or Paint Body and Equipment (PBE) distributors and are available from the local Jobber (store) where you buy your paint and supplies. For a distributor near you, see our Where to Buy section.

You can download manuals and instruction sheets on our website here.

For support or repair service, contact us Monday through Friday from 8 am to 5 pm Pacific time, Toll Free from the U.S. and Canada at 800-227-2822 or use the Contact section of our website. For warranty service, contact the distributor from which you bought the product.

Successful pin welding and pulling requires a strong weld and a strong weld depends on several factors:

First, check that power is connected and circuit breakers/fuses are not tripped. The circuit breaker on the welder case must be reset manually if it trips.

For best results, welder should be connected directly to a properly rated electrical outlet. The use of extension cords can reduce welding power. If an extension cord must be used, it should be as short as possible and of the highest possible gage (12 AWG recommended).

The panel to be welded must be prepped to clean bright metal and be free of paint, primer, dust, grease and rust.

Weld pins must be clean and have a bright copper finish. Do not use old or corroded pins.

The electrode ground tube on the welder must be free from carbon and oxidation. Clean the tube with a wire brush to bright copper.

Too short a weld time will result in a weak weld. Increase weld time until a strong weld is achieved.

Click here for a handy Troubleshooting Tips guide.